Reasonable chemical composition and pure steel quality are the prerequisites to ensure the electromagnetic properties of silicon steel sheets. The heat treatment process is a key process to improve the electromagnetic properties of silicon steel sheets.

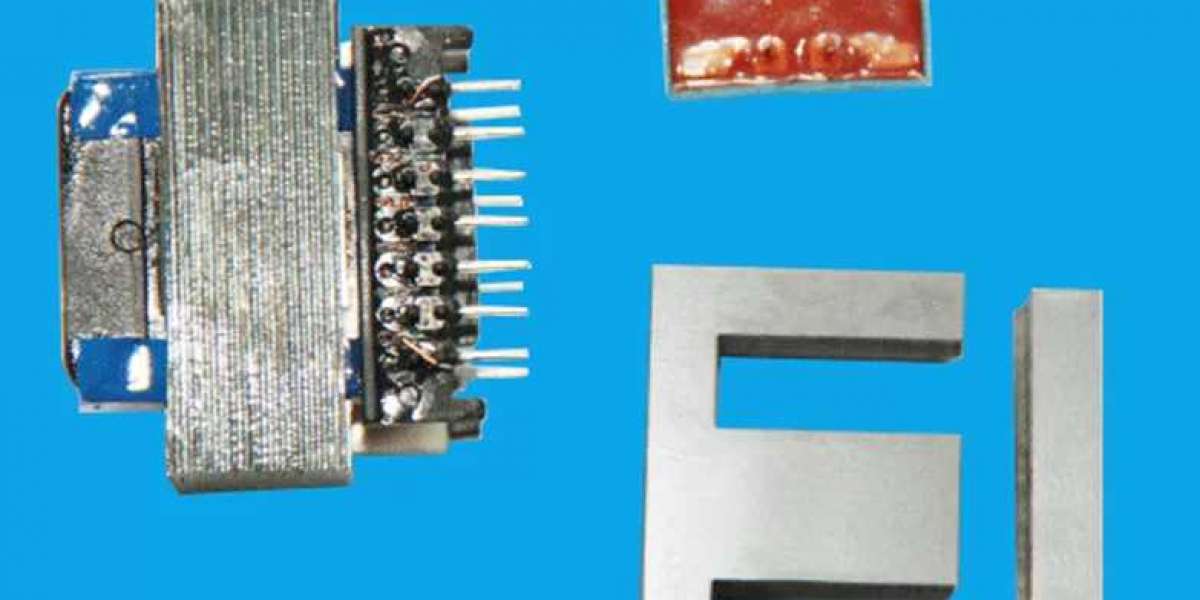

Electrical silicon steel is actually an iron-silicon alloy with 1%~4.5% Si added to industrial pure iron. It has a silicon-containing single-phase ferrite structure at room temperature. The production process of high-performance silicon steel sheets is: smelting a billet with a given silicon content and a minimum carbon content (in fact, generally about 0.05%C), and then hot rolling into a steel strip with a thickness of about 2.5mm, and finally cold rolling is commonly used Thin steel sheet with a thickness of 0.35-0.5m. Annealing should be carried out before cold rolling, and the carbon should be reduced to less than 0.02% in this process; finally, high-temperature annealing of finished products should be carried out to eliminate work hardening and coarsen grains. These two annealings are the most typical and important heat treatments in the production of silicon steel sheets.

If the degree of cold rolling deformation is large (45% to 60%), a textured structure is obtained, and the degree of orientation is about 90%; if the degree of cold rolling deformation is small (7% to 10%), the orientation is obtained. small organizations. If the silicon steel sheet is only rolled in a hot state, the texture will not be obtained, and the properties along the rolling direction and the vertical rolling direction are the same. Therefore, according to the characteristics of texture orientation, silicon steel sheets are divided into non-oriented hot-rolled silicon steel sheets, low-oriented cold-rolled silicon steel sheets and oriented cold-rolled silicon steel sheets.

(1) Heat treatment of hot-rolled silicon steel sheet. Hot-rolled non-oriented silicon steel sheet is a low-carbon killed steel slab containing silicon, which is made by continuous hot rolling or laminated hot rolling. Finished products are annealed in continuous slot furnaces, chamber furnaces or continuous strip furnaces. The annealing temperature and time vary depending on the type of silicon steel sheet and the production process. Generally, the heat preservation is at 700-1200 °C for one to several days, and the protective gas is passed through the furnace. Through stress removal, decarburization and grain growth, the product can meet the performance requirements.

(2) Heat treatment of cold-rolled non-oriented silicon steel sheet. It is produced by one-time cold rolling or critical deformation method, and its technological process is: smelting → ingot casting → rough rolling → hot rolling → pickling → cold rolling (→ intermediate annealing → critical deformation) → finished product heat treatment.